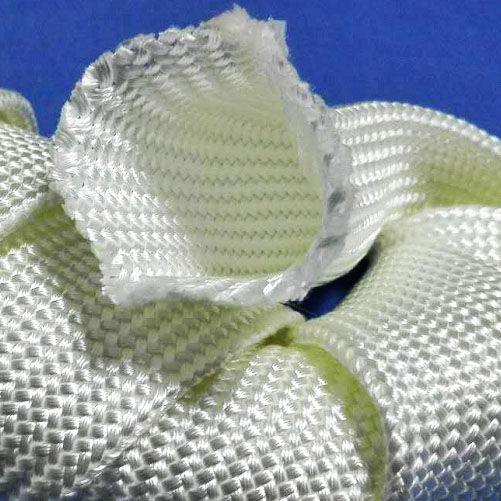

S-glass fiber woven roving is a premium composite fabric known for its elevated mechanical properties when compared to standard E-glass woven roving. With its higher tensile strength and stiffness, S-glass provides an enhanced structural performance, making it a go-to choice for industries where superior strength and reduced weight are critical. Unlike the more commonly utilized E-glass, which is sufficient for general-purpose applications, S-glass is sought after for advanced applications in aerospace, defense, marine, and high-performance sporting equipment where the demands on material durability and resistance to stress are greater. The use of S-glass woven roving facilitates the creation of components that not only bear heavier loads but also withstand harsher conditions, solidifying its role in the production of high-end, resilient composite structures.

Feature:

- High Strength-to-Weight Ratio:

S-glass has one of the highest strength-to-weight ratios among glass fibers. This means that S-glass woven roving is extremely strong while still being lightweight, making it ideal for aerospace, automotive, and marine applications.

- High Modulus:

It has a higher modulus of elasticity (stiffness) than E-glass, which gives it superior resistance to deformation under load.

- Good Impact Resistance:

S-glass fibers offer excellent impact resistance, meaning they are less likely to crack or break under force. This makes them ideal for structures that are subject to impact or high-stress environments.

- Corrosion Resistance:

Like all glass fibers, S-glass is resistant to most chemicals and corrosion, making it durable in harsh environments such as marine, industrial, and chemical processing applications.

- High Thermal Stability:

S-glass fibers can withstand higher temperatures compared to E-glass, which is beneficial in applications where high heat resistance is required.

Application:

- Aerospace:

Used in aircraft components such as fuselage sections, wing spars, and other structural parts where strength and low weight are critical.

- Marine:

Commonly used for boat hulls, decks, and other marine applications because of its resistance to water and impact. It also enhances the durability of boats and ships.

- Automotive:

S-glass roving is used in automotive components such as body panels, underbody parts, and reinforcement structures where high strength and low weight are desired.

- Wind Energy:

S-glass woven roving is used in the construction of wind turbine blades due to its lightweight and strength properties, contributing to better performance and durability.

- Sports Equipment:

It is often used in sports equipment like tennis rackets, skis, and fishing rods, where high strength and low weight are needed for performance.

- Industrial Applications:

S-glass can be used in the manufacturing of tanks, pipes, and other structural components in harsh environments like chemical processing and oil rigs.

Specification:

Code | Warp and Weft | Count(ends/cm) | Weight(g/m2) | Breaking Strength(N/25mm) | |

SWR400 | 660 | W3.0 | F3.0 | 400 | W2700 F2700 |

SWR800 | 1980 | W2.0 | F2.0 | 810 | W4950 F4950 |

*Specific products could be made according to customers’requirements.