Para aramid staple fiber is highly resistant to heat and flame, while also providing excellent strength. It can withstand temperatures of up to 220° C for more than 10 years and up to 240° C for 1000 hours. Available in different lengths and densities, it is suitable for spinning and non-woven processes. Its applications include engineering plastics, friction materials, reinforcing materials, and lightweight composite materials for various

industries.

Feature:

- High Strength and Durability:

Para-aramid fibers are known for their outstanding tensile strength, which is several times higher than that of steel on an equal-weight basis. This makes them incredibly durable and resistant to stretching or breaking under stress.

- Thermal Resistance:

They can withstand extreme temperatures without melting or decomposing, making them ideal for applications requiring high thermal stability.

- Lightweight:

Para-aramid fibers are remarkably lightweight, which is beneficial for applications where high strength-to-weight ratios are critical, such as in aerospace and automotive industries.

- Chemical Resistance:

These fibers exhibit excellent resistance to chemicals, solvents, and abrasion, further enhancing their durability and lifespan in harsh environments.

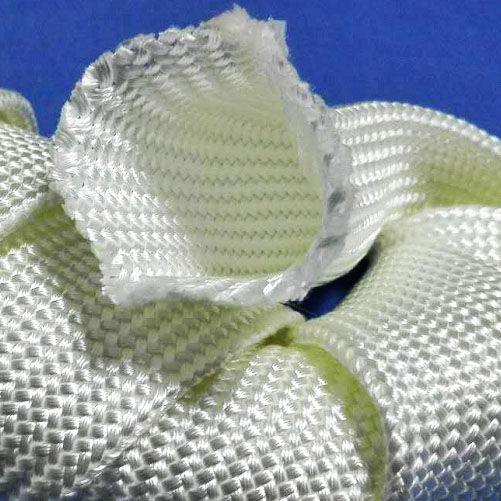

- Flexibility:

Despite their strength, para-aramid fibers are flexible and can be woven into fabrics. This makes them versatile for a wide range of applications.

- Low Electrical Conductivity:

They have low electrical conductivity, making them suitable for use in electronic and electrical applications.

Application:

- Protective Gear:

They are used in the manufacturing of bulletproof vests, firefighting uniforms, cut-resistant gloves, and other protective clothing due to their high strength and thermal resistance.

- Reinforcement Materials:

In the automotive and aerospace industries, para-aramid fibers serve as reinforcement materials in composite components. They contribute to the production of lightweight yet strong parts, such as body panels and structural elements.

- Filtration:

Given their chemical and thermal resistance, para-aramid fibers are used in high-performance filtration applications, where they help in filtering out hazardous materials at high temperatures.

- Ropes and Cables:

Their high strength and durability make them ideal for ropes and cables used in critical applications, including mooring lines, parachutes, and suspension bridge cables.

- Rubber Reinforcement:

Para-aramid fibers are used to reinforce rubber in tires, belts, and hoses, enhancing their strength and durability without significantly increasing weight.

- Electrical Insulation:

Due to their low electrical conductivity, these fibers find applications in electrical insulation materials, helping to enhance safety and performance in electrical and electronic components.