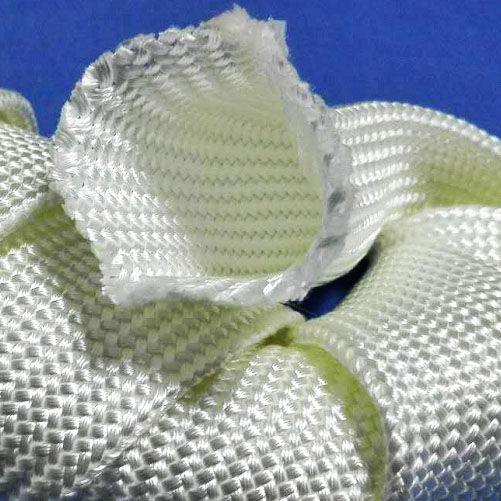

High silica needle felt is a premium grade material designed for exceptional thermal insulation and protective applications, particularly in environments demanding high-temperature resistance. This material is composed of high silica fibers, capable of withstanding continuous temperatures up to 1000° C (1832° F), making it ideal for use in industries like aerospace, automotive, and heavy machinery. The needle-felt construction enhances its density and structural integrity, allowing for effective heat barrier properties and durability against thermal shock. Its inherent non-combustible nature and excellent thermal insulation capabilities ensure safety and efficiency in various high-heat settings. High silica needle felt is also customizable in terms of thickness and density, catering to specific industrial requirements and providing versatility for thermal management solutions in high-stress environments.

Feature:

- High-Temperature Resistance:

High silica needle felt can withstand continuous exposure to temperatures up to 1000°C (1832°F) and can tolerate short-term exposure to even higher temperatures. This makes it an ideal material for high-heat environments.

- Low Thermal Conductivity:

The material has very low thermal conductivity, which makes it an excellent insulator. This property is crucial in applications requiring thermal barrier materials to prevent heat transfer.

- Chemical Stability:

Silica fibers are highly resistant to most chemicals, including acids and alkalis, which makes high silica needle felt suitable for use in corrosive environments.

- Dimensional Stability:

Even at high temperatures, high silica needle felt maintains its shape and size, resisting shrinkage and deformation. This dimensional stability is vital for manufacturing processes and applications where precise measurements are critical.

- Fire Resistance:

It is inherently fire-resistant and does not burn, melt, or emit toxic fumes, making it safe for use in fire-prone environments.

Application:

- Industrial Furnaces:

Used as insulation in furnaces, boilers, and kilns in the metallurgy, ceramics, and glass industries, where high temperature stability is required.

- Aerospace:

Employed in the aerospace industry for thermal insulation in aircraft and spacecraft. It helps in protecting critical components from extreme heat generated during operations such as re-entry or high-speed travel.

- Automotive:

Used in automotive applications for heat shielding components in engines and exhaust systems to protect sensitive parts from heat damage.

- Electrical Insulation:

Its thermal and fire-resistant properties make it suitable for use as electrical insulation in high-temperature environments.

Specification:

Code | Size(mm) | Thermal Conductivity (w/mk@800°C) | Working Temperture(°C) | Density (kg/m3) | Weight (g/m2) | ||

Thickness | Wdith | Length | |||||

HSF908 | 5/10/12/15/20/25 | 1000/1520 | 10/20/30/50 | <0.14 | 1000 | 130-180 | 650-4500 |

*Specific products could be made according to customers’requirements.