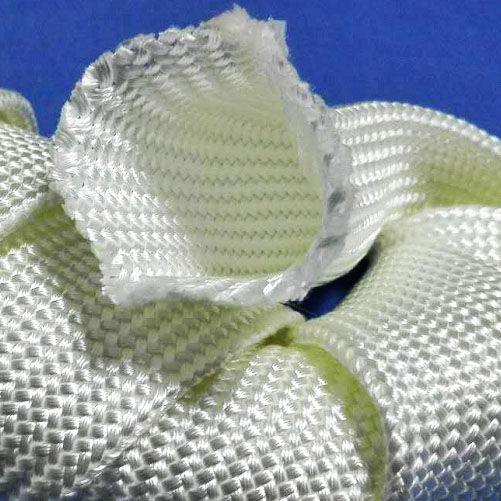

High silica sewing thread is a specialized industrial product crafted from high-strength, high silica twisted yarn, which is treated with PTFE (polytetrafluoroethylene) dispersion to enhance its performance and durability. This thread is designed to retain its integrity in extreme conditions, with a silica content typically above 96%, allowing it to withstand continuous temperatures up to 1000° C and short-term exposure up to 1650° C. The PTFE coating not only improves the thread's chemical resistance, particularly against acids and alkalis, but also enhances its lubricity, making it easier to sew and less prone to breaking under tension. Ideal for high-temperature industrial applications, high silica sewing thread is used extensively in the manufacturing of fireproof garments, heat-resistant fabrics, and aerospace and automotive components, where reliability and resistance to harsh environments are paramount.

Feature:

- High Temperature Resistance:

High silica sewing thread exhibits excellent high - temperature resistance, capable of withstanding extremely high temperatures. Generally, its continuous operating temperature can reach up to 900°C or even higher, and the instantaneous operating temperature can reach 1400°C.

- High Strength and High Modulus:

It has high tensile strength, enabling it to withstand significant pulling forces without breaking easily during the sewing process. At the same time, it has a high modulus, making the sewn items more stable and secure.

- Fire - Proof and Flame - Retardant:

The sewing thread made of high - silica - oxygen fiber is non - flammable by itself, belonging to Class A non - flammable materials. It can effectively prevent the spread of flames and reduce fire risks.

- Chemical Stability:

It has good resistance to many chemical substances, including acids, alkalis, and various organic solvents. It can maintain stable performance in harsh chemical environments and is not easily corroded chemically.

- Insulation and Antistatic Properties:

It has excellent electrical insulation properties, effectively preventing the passage of electric current. Additionally, it has antistatic characteristics, reducing the generation and accumulation of static electricity and avoiding various problems caused by static electricity.

- Weather Resistance and Aging Resistance:

High silica sewing thread can resist the influence of various natural environmental factors, such as ultraviolet radiation, humidity, wind, and rain. It is not prone to aging, embrittlement, or deterioration, and can maintain good performance during long - term use.

Application:

- Fire - Fighting and Safety Fields:

It is used to make fire - proof clothing, fire - proof curtains, fire - proof blankets, fire hoses, and other fire - fighting equipment, providing reliable fire protection for firefighters and relevant personnel.

- Industrial High - Temperature Environments:

In high - temperature industrial productions such as steel, metallurgy, glass manufacturing, and foundry, it can be used to sew high - temperature protective curtains, heat - insulation covers, and insulation sleeves to protect equipment and personnel from high - temperature hazards.

- Aerospace and Automotive Industries:

In the aerospace field, it is used to manufacture thermal insulation materials and sealing components of aircraft. In the automotive industry, it can be used to sew heat - insulation covers of the engine compartment and insulation sleeves of the exhaust pipe, improving the safety and performance of vehicles.

- Electrical Insulation Field:

It can be used as the insulating layer material of wires and cables, as well as the sewing thread for insulating components in electrical equipment, ensuring the safe operation of the electrical system.

- Filtration and Separation Field:

It is used to make high - temperature gas filter bags, liquid filter cloth, and other filter materials, achieving efficient filtration and separation functions under high - temperature working conditions.

Specification:

Code | Diameter (mm) | Linear Density (tex) | Tensile Strength (N) | SiO2 (%) | Moisture Content (%) | LOI (%) | Working Temperture (°C ) |

HCT9-200SB | 0.45±0.05 | 200+20 | ≥40 | ≥96 | ≤3 | 18.0±2.0 | 1000 |

HCT7-216SB | 0.45±0.05 | 216+20 | ≥54 |

*Specific products could be made according to customers’requirements.